Materials at the nanoscale lie between the quantum effects of atoms and molecules and the bulk properties of materials. It is in this ‘no-man’s-land’ where many physical properties of materials are controlled by phenomena that have their critical dimensions at the nanoscale.

Nanomaterials cover a huge diverse range of materials, such as polymers, metals, ceramics, sol-gels, powders, flexible IC and screens, biotech markers, etc.

The application of emerging quantum dots technology will affect all aspects of chemical and biological countermeasures, from improving physical protection, refining the sensitivity and selectivity of sensors, to advancing decontamination against bacteria attack and biological weapon and also printable medical diagnosis kit during the war.

BIODEFENSE MATERIALS

Indeed, functionalized quantum dots we have produced have the potential to detect single molecules of a target substance. For example, integrated custom devices using functionalized quantum dots could better detect solid particles and/or liquids with low vapor pressure, such as high explosives or nerve agents.

Also, functionalized quantum dots can be designed for detection of specific biological moieties, which may lead to detection methodologies for infectious diseases or anthrax spores.

Therefore, all these examples demonstrate the undeniable potential and benefits of functionalized quantum dots in Bio-Defense industry.

Antimicrobial plasmonic colloids: Issued by ATTONUCLEI’s R&D laboratory, we have produced metalic colloids functionalized with hydrophilic polymers allowing their aqueous dispersion. These plasmonic colloids designed for their antibacterial properties by production of oxygen reactive species and/or disruption of the bacterial membrane. The antimicrobial activity and efficacy of the colloids is related to their engineered size and custom functionalization.

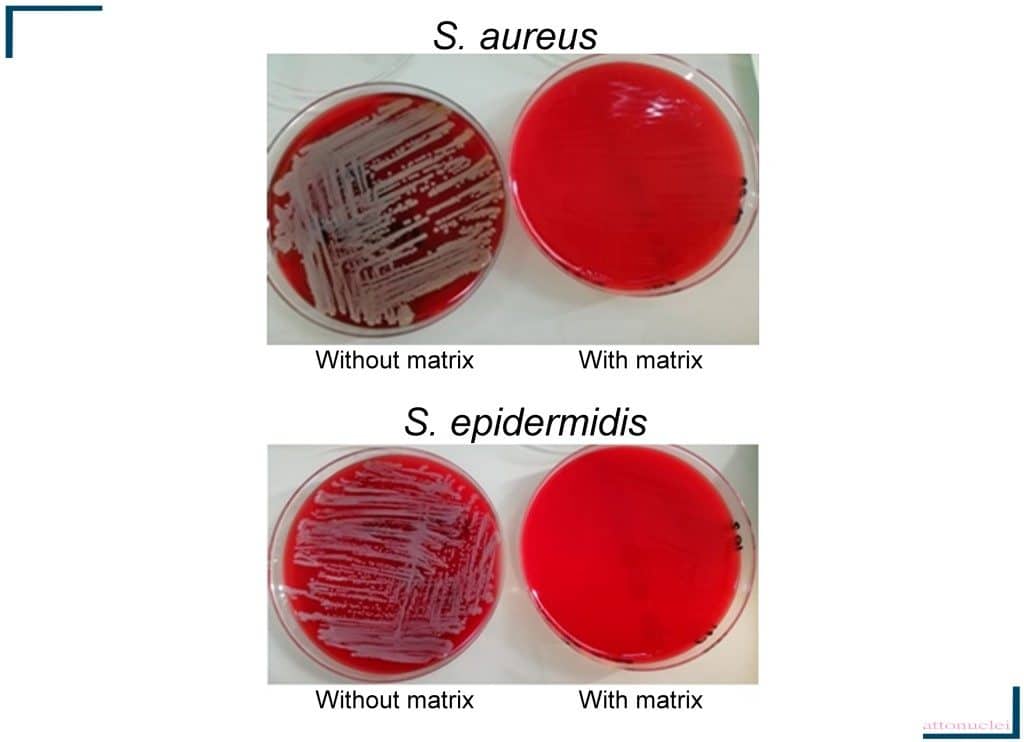

The antimicrobial efficacy of our colloids was assessed at the University Hospital of Nantes (France), by incubating low pathogenic (S. aureus) and commensal (S. epidermidis) bacteria burdens (102/mL) with the colloidal hydrogel matrix. The viability of these bacterias was then assessed by analyzing a 24h culture on blood agar medium.

Bacteria were not detectable at all after contact with the matrix, demonstrating its bactericidal activity.

SMART COATING

ATTONUCLEI is the first company in the world to develop “colourless long-term intelligent surface coating” with a hydrophobic, photocatalytic and antibacterial effect in one concept that can be use in several industrial applications.

Antibacterial protection : Antibacterial materials is one of the sectors getting much more interest. For exemple, an antibacterial property can be given to a textile material at its final finishing stage by using antibacterial quantum dots. Antibacterial quantum dots on the textile will destroy undesired bacteria by touching them and provide more healthy conditions for human life. Theses antibacterial nanoparticles have an impact on a variety of bacteria such as e. coli, salmonella, s. aureaus and in addition, can select the bacteria to be destroyed depending on their designed morphology.

Photocatalytic effect : By its photocatalytic effect, the coating can both improve the efficiency and reduce the maintenance needed for any photovoltaic system. Indeed, self cleaning property of quantum dots is based on their photocatalytic activities. The photocatalytic quantum dots decompose the contaminants on the surface when they are illimunated by light and decomposed contaminants are easily moved away from the surface by water.

Hydrophobic effect : In nature, the leaves of the lotus plant are seen clean in spite of the fact that they are living in dirty conditions. The leaves of the lotus plant clean themselves via a repelling mechanism. In principle, the reduced adhesion forces between water molecules and the leaves make water molecules more spherical on the leaves and hence more water repellent, leading to dust free surfaces. Analogously, water and/or oil repellent surfaces can be created by using our nano-scale triple action coating.

The very weak surface free energy generated by this type of coating improves sliding effects between to identical coated surfaces or even between a coated and a non coated surface of foreign matter. These coatings allow to obtain very high contact angles with various liquids such as polar liquids , apolar liquids , mixt liquids, oils, etc.. The surface energy obtained on such coated substrates are lower than PTFE. These coatings possess a very strong affinity for the substrates they coat. For selected materials, the covalent bonding induces a strong resistance to abrasion, to chemical or physical wear.

This kind of coating can for example be useful for solar panels. Indeed, they need to have a clean surface to efficiently absorb light from the sun, but they are often soiled by bird faeces, dust, pollen, water and other particles. Therefore, a dirty solar panel can reduce its full power capabilities by up to ~25 percent.

The nano-scale coating repels dust, pollen, water and other particles by the triple physico-chemical actions, hydrophobic, photocatalytic and antibacterian without hindering the solar panel’s ability to absorb sunlight. Indeed, the layer is so thin that it does not scatter light, and therefore, does not interfere with the initial solar panel’s performance.The nano-scale thin surface coating can maintain this ideal hydrophobic surface for years and reducing overall maintenance.

As the water is repelled by the nano-scale triple action treated surface it will also pick up and carry away the dust and dirt, thereby cleaning the panel naturally.

Otherside, this coating is user friendly and environment friendly and simple coating process is performed in a few minutes therefore this process do not use fluorinated solvents to avoid environment pollution or regulatory constraints. The nano-scale triple action coating can be applied to a variety of surface materials, including glass, aluminum, ballistic missile, cloth fibers, aeronautic, wood, textiles, watch movement, plastic, etc..

TECHNICAL TEXTILE

The impact of nanotechnology in the textile area has brought up innovative finishing processes. Nanotechnology not only has exerted its influence in making versatile fiber composites but also has upgraded chemical finishings, making them more controllable and more thorough.

Ideally, discrete quantum dots finishings can be applied to designated sites on textile materials in a specific orientation and trajectory through thermodynamic, electrostatic, conductive or other technical approaches.

One of the trends in synthesis process is to pursue a “functionalized custom quantum dots” emulsification. Indeed Finishings can be emulsified into nano-micelles, made into nano-sols or wrapped in nanocapsules that can adhere to textile substrates more evenly. These advanced finishings set up an unprecedented level of textile performances of stainresistant, hydrophobic, antibacterial, antifungic, anti-static, wrinkle resistant, flame resistant, abrasion resistant and shrink proof abilities, etc..

SECURITY TAGS

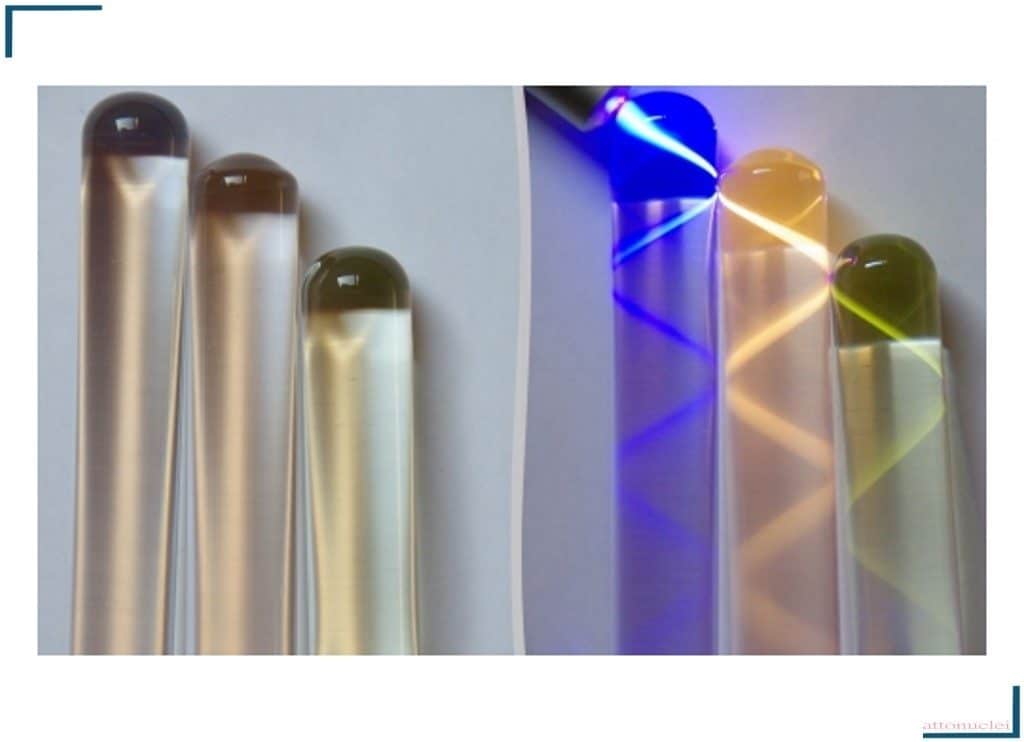

At ATTONUCLEI, we’ve formulated ultra stable inks and high temperature resistant paints that can be applied to any surface, including paper, plastic or metal. Our inks and paints incorporate quantum dots and semiconductor nanoparticles, which can be tuned to emit light at specific wavelengths in the visible and infrared portions of the spectra.

The quantum dot based inks may be applied via conventional screen, flexographic, offset, gravure, and ink jet printing processes while the paints are designed to be sprayed onto any surface.

They are unique colorants that are used in security inks, fibers, papers, embedded dots, labels, unique fluorescent spectral barcodes, paints, plastics, special effects and tracers, product identification, authentication, dual images, art, crafts and anti-counterfeiting applications.

Indeed ATTONUCLEI’s custom quantum dots produce specific and spectrally pure colors dependent on their chemical compositions and dimensions under specific light. They seem fully colorless (invisible) under the typical day light, however, exhibits their characteristic colors under the right excitation conditions making them convenient materials for high security applications. Invisible quantum dots covert markers can range from sub-nanometers to several nanometers in size and can be integrated into many types of products and materials. They can be directly incorporated within the product, on the product (via sprays or atomizers, coatings, inks/varnishes or hang tags) or as part of the packaging for films, bottles, paper products and blister packs.

Moreover, by the printing process, the two or three dimensional shape created on the surface together with its unique color and intensity distribution offer us a new inimitable spectral barcodes.

ATTONUCLEI’s “invisible quantum dots security solutions” can be applied to many items such as pharmaceutical packaging, medicinal tablets, tobacco packaging, watches, jewelry, automotive and aerospace components, IC’s packaging, electromechanical switches, leather objects and many other manufactured parts and components.

Typical quantum dots applications for security:

• Brand protection against counterfeiting and track & trace of unsolicited importation (gray market) via primary packaging, secondary packaging and printed instructions.

• Document security for value documents, certificates, identification documents, contracts, etc..

• Security printing for offset, rotogravure, flexo, laser, inkjet both for individual and industrial printing.

• Adaptable to customer specific needs and integrated into existing workflows.

Therefore, ATTTONUCLEI’s custom quantum dots markers place your brand fingerprint on or inside your product as an invisible assurance that your customers are receiving a genuine article.

ATTONUCLEI also exclusively designs photoluminescent quantum dots for industrial security and anti-counterfeiting applications.